From T-shirts and jeans to high-end bespoke suits, Raleigh has a blossoming fashion industry. We spent time with these three movers and shakers to learn how — and why — they make custom and ready-to-wear apparel right here in the capital city.

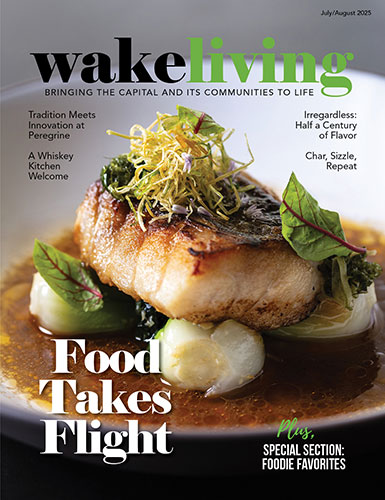

John Pugh, Founder/Owner

House of Swank

House of Swank founder/owner John Pugh gets ready to play a homemade guitar crafted from an old Fritos lunchbox.

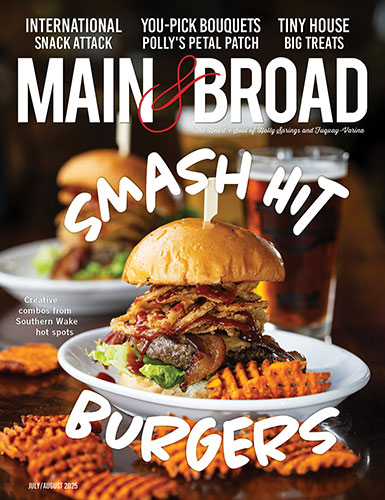

It all started with a Fritos lunchbox and an old piece of wood found in the basement of a former apartment. John Pugh used these items to fashion a three-string guitar he would use to play gigs around town as Johnny Swank. Eventually, he needed some merchandise. “So, I made five shirts,” said Pugh. “I learned how to screen print poorly in our little kitchen of our little apartment.”

He sold those shirts, made more, and it just kept going from there. Eleven years later, it’s his full-time job as the owner of House of Swank on East Hargett Street in Downtown Raleigh.

T-shirts in production at House of Swank.

For those who aren’t already familiar with House of Swank, you’ve probably seen their T-shirts on a hip friend of yours or even on social media. Remember the big North Raleigh spitting cobra ordeal last summer? Well, that became a T-shirt. “The cobra was ridiculous,” said Pugh. “At first, I wasn’t going to do anything with it, but as the day went on and on, it got more stupid every hour. By the time we were eating dinner, I finally knew what I wanted to do.”

Pugh created a design in the vein of a sports team, the “North Raleigh Spitting Cobras.” It sold well. But like his other designs, it’s pretty much trial and error. “There’s a ton of stuff you throw out in the world and two people buy it or no one buys it,” he said. “It’s not like we’re product testing and getting these focus groups and all that kind of stuff. It’s more like, ‘I really want this shirt for myself, and I might as well make 10 more and see if I can sell them.’”

House of Swank t-shirts feature designs that speak to North Carolinians.

His most popular shirt shows a simple outline of the state of North Carolina with the left half of the state represented by the word “Tomato” and the right side by “Vinegar,” an homage to how North Carolinians prefer the sauce on their barbecue.

And the ideas just keep coming. “I just me keep an eye on things and, basically, we always say we have job security as long as someone says something stupid,” Pugh said. “I’m a total political junkie, so I’m all over that kind of stuff, too. It’s a terrible habit, but it’s worked pretty well.”

Jud Burnette makes t-shirts in the back of the retail store in downtown Raleigh.

Customers also flock to the designs that demonstrate place attachment, which Pugh is happy to “dork out” on and discuss. “So the theory is that people are into their own place, and we always wanted to have it so people can represent themselves,” he said. “People like to represent where they’re from, be it the state of North Carolina or the cities. It’s super localized pride, even at the neighborhood level. It’s like the North Carolina shirt. I just wanted to have something with the state of North Carolina that wasn’t like UNC or NC State. I just wanted the state on my shirt. I couldn’t find it. So I made it.”

Buttons, hoodies, hats, dog bandanas, and stickers are among some of the items made at House of Swank.

All the designs are mix of Pugh’s own hand-drawn art, along with some purchased images, which he usually manipulates in some fashion. With his business partner/wife and a handful of employees, he prints all the designs in-house in the back of their retail store. And it’s not just T-shirts. It’s hoodies, hats, dog bandanas, coasters, stickers, and just about anything you can think of to print a design on.

“We are increasingly doing more printing, more shirts at a time,” said Pugh. “It could range from anywhere from 10 shirts to 500 a day.”

As Pugh showed us his Fritos lunchbox guitar and even played a few riffs as Johnny Swank, you can tell this is a creative guy who found a niche in local fashion and enjoys every minute of it.

“I like the creativity and the fact that I can do a lot of different things on any given day. Like today. I did some design work for new shirt. I went to deliver some stuff in Durham. I talked to some folks in Durham. We were burning some screens,” he said. “I need to be doing lots of different stuff. I’ve worked in corporate before, and that would just drive me insane. I can’t do that. There’s no way. It’s a really wide, diverse skill set that I’ve developed, and it’s been fun to learn.”

Victor Lytvinenko, Founder/Owner

Raleigh Denim

Victor Lytvinenko, founder/owner of Raleigh Denim, in his retail store and factory in Raleigh’s warehouse district

Walk into Raleigh Denim on W. Martin Street in the Warehouse District and you immediately notice hundreds of brown paper airplanes lining the ceiling, carefully suspended above what you are there to really check out: jeans. More to the point, locally made jeans, made right behind the retail store in a workshop that can easily be viewed while shopping.

“It was Sarah’s idea,” said Victor Lytvinenko of the paper planes. His wife and business partner Sarah Yarborough suggested them as a nod to the NC saying “First in Flight.” “It’s a warehouse space, and when we moved in, we were pinching pennies pretty tight and needed to transform it. We love how when you walk into an art gallery it changes your perspective, makes you take a deep breath; you feel a little lighter. We wanted this place to feel transformative. And so this was a way to create a lot of volume, make it a very fun and interesting place to visit because the store is an installation. The store is an art piece on its own.”

Behind the scenes at Raleigh Denim.

You could say Lytvinenko has always been interested in the arts, beginning with the culinary arts. He was a cook at Nobu in New York City in 2001, and also worked in the kitchen at Raleigh’s Second Empire. Before that, he was into wine-making (and still does a little on his small farm north of Durham). But it was when he was in the mountains of North Carolina that he met people who used to work in denim factories, especially Cone Mills in Greensboro, which has been making denim for 130 years.

“I just took a lot of the philosophies of wine-making and cooking, farm to table, and applied it to denim,” said Lytvinenko. “We had all these building blocks in North Carolina because it was where the best denim in the world was made for a long time. And we just started making jeans in our apartment. We bought two or three sewing machines off of Craigslist and I just started making a pair of jeans every day and fell in love with it.”

At Raleigh Denim, jeans are made and displayed like works of art

That was in 2006. He made about 500 pairs before he found one he liked. Then, like most smart businessmen, he sought out mentors.

“Our pattern-maker, she’s close to 90, and was the pattern-maker at Levi’s in the 1950s and ’60s. We worked together for a decade for four or five hours a day, every day,” said Lytvinenko. “I also found pretty talented guys up in the mountains who used to run the last Levi’s factory that was in America. It was in Bakersville, North Carolina. They taught me a lot about sewing machines and how to fix them. I would put my broken machines in the back of our car and drive it up to the mountains and we would fix them in their garage, and it was kind of an informal apprenticeship where I really wanted to learn. They were retired and their industry had moved overseas, and I think they were just excited to share and excited that somebody younger was interested in their expertise.”

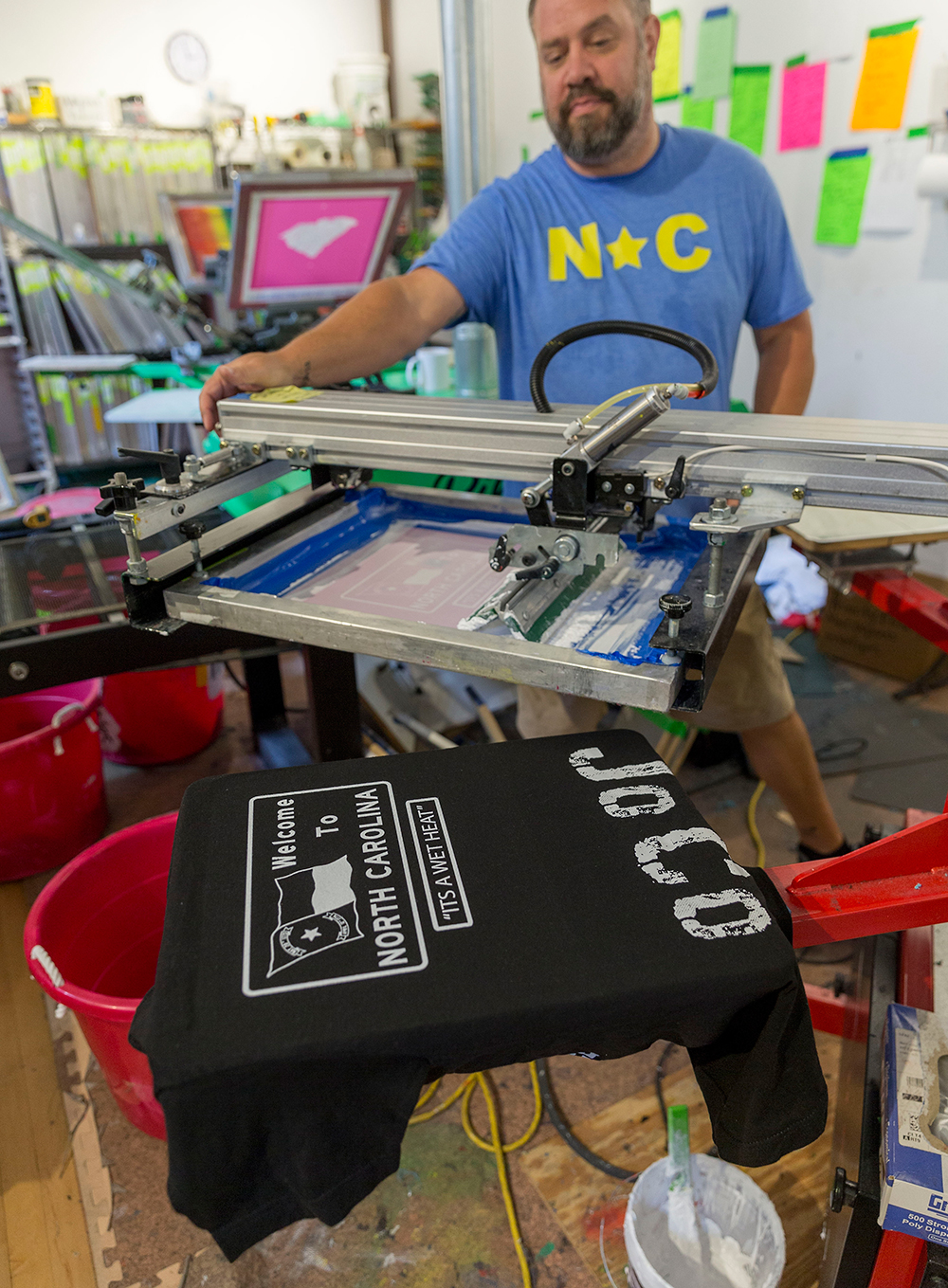

Each pair of jeans is hand-signed by the person who made them.

To date, Lytvinenko has rebuilt every machine in the factory. And he loves his old fixer-uppers, “not because they’re vintage or because it’s cool, but because they do the best job.”

And nothing less than the best is what you can expect from Raleigh Denim. “Compare chicken that is grown on a farm next door to a McDonald’s chicken nugget,” said Lytvinenko. “It’s about where it comes from, how it’s made, how it’s grown, how it’s processed. We’re doing things at a higher quality at every level, from the cotton to the way that we weave it to the way we cut it.”

Spools of fabric will eventually make their way into one of the several clothing items made at Raleigh Denim.

The jeans’ price point ranges from about $200-$500, but keep in mind it takes about 10 times longer to make a pair of Raleigh Denim jeans than a pair of Levi’s. Lytvinenko also does all the design work himself. And for a company with only a 23 employees, they do the work of many more.

Each article of clothing is carefully crafted by hand.

“It’s kind of crazy that we’re able to do what we do at the scale that we’re doing it with so many levels of expertise that’s necessary to get it through the whole pipeline from design to fabric, sourcing, pattern-making, cutting, sewing, quality control, bagging, tagging, and sales,” he said.

The end result is a pair of jeans you’ll have for years. And just like the wine-making he enjoys, they just get better with age.

“I wanted to make something that gets better over time, said Lytvinenko. A lot of my clothes would wear out, and I wanted something that would wear in. It’s a reflection of your muscles, your bones, the way you live, where you’ve been, and what you do. And I think, informally, it’s like sharing your life story visually through this medium.”

Not to mention jeans are probably the most popular piece of clothing worldwide and can be worn anytime and anyplace. “Jeans have this nonchalance about them,” said Lytvinenko. “It’s this tightrope of almost extremes where it can be the most ripped up thing in the world and the most fashionable at the same time. It could be super clean and dark and you can wear it with a blazer, or you can wear the same jeans with a T-shirt and flip flops.”

One of many vintage sewing machines still in use at Raleigh Denim.

For his dedication to his art, Lytvinenko is getting inducted into Wake County Public School Hall of Fame this October. He attended Enloe High School, where he met his wife more than 20 years ago. And earlier this year, Raleigh Denim added to their executive team to help expand the brand and become a larger business. “We’ve got some ideas on creating lines of products — clothing and other products, too, that could propel us into another stratosphere,” said Lytvinenko.

Lytvinenko points to the entrance of the factory from the retail shop.

He and his wife have already been designing for Bernhardt Furniture in Lenoir, NC, for a decade, and are always looking for new opportunities. “Every year we learn more; we dig a little deeper; we push a little harder,” said Lytvinenko. “Our interest is in making the best thing that we possibly can. What we’re doing here is very special.”

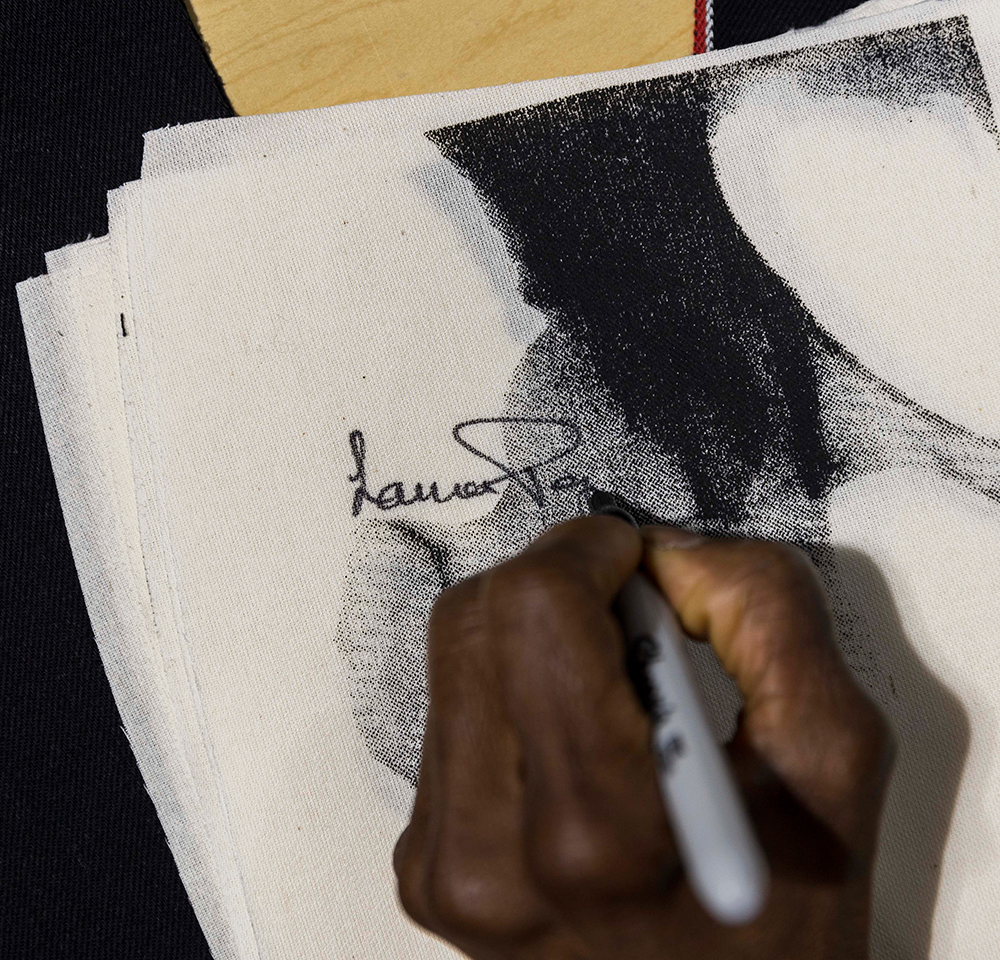

Brian Burnette, Founder/Owner

Glenwood South Tailors & Men’s Shop

Brian Burnette, founder/owner of Glenwood South Tailors & Men’s Shop, always has a measuring tape nearby.

Whether you’re meeting Brian Burnette for the first time or you’ve known him for years, you’ll probably surmise he’s pretty much always the best-dressed person in the room. That’s because it’s his job to know what looks good. After working in menswear at Nordstrom for four years, he learned what professionals and executives really look for when they’re investing in clothing. And back in 2015 when he was looking to get some suits tailored in Glenwood South and realized there were no businesses in a five-mile radius to meet his needs, he had a lightbulb moment.

A peek into the alterations room at Glenwood South Tailors & Men’s Shop.

“It just hit me,” said Burnette. “I knew that more professionals and executives from the Midwest and the Northeast were coming here, and I know how important tailoring, alterations, and that experience are, and I said, ‘I think we might have something here.’”

He signed a lease for an 800-squarefoot space that was upstairs from his current 2,800-square-foot location on W. Johnson Street, and this October will be seven years in business. The expansion allowed him to create a well-appointed space that allows for custom tailoring on one side, ready-to-wear on the other, and an in-house sewing shop in the back.

Burnette uses a pincushion from turkey while fitting a client.

It’s all about the “bespoke” experience — a word you hear these days referring to everything from a cocktail to a luxury vehicle. “The word ‘bespoke’ actually comes from Europe and means to be spoken for,” said Burnette. “Gentlemen would go to their local tailors and cutters and would say, ‘I would love to have a suit cut in that cloth.’ And then that cloth would be spoken for. Now, bespoken means when you have something that’s cut from a pattern to your specifications, your dimensions, your likes, your taste, and your interests. And what that has done is actually emboldened our clients to seek us out because they want to go to a subject matter expert who understands their pain points when it comes to designing a wardrobe, and someone who understands their business environments.”

Julia shows what a jacket looks like about halfway through a bespoke experience.

About 90% of Burnette’s clients come to him for an entire wardrobe, even asking him to choose the pieces himself. “They’ll say ‘you pick’ because they know I’ve had the four years of styling experience at Nordstrom,” he said. “Sometimes I say, ‘Hey, you’ve got five sport coats and they’re all navy blue. It’s time to add some color. And that’s really cool because they trust us and know what I pick out will be business appropriate, but they can also wear it out on date night with their wife, as well. It’s really humbling for me.”

Burnette’s core customers are professionals, typically in the biopharma industry, consulting management, or senior VPs. “People who really care about their image. Our clients are also very time-sensitive. I think one of the best ways I heard someone sum it up is that our clients are the people who are more interested in investing money to save times versus spending time to save money,” said Burnette.

The bespoke experience, which about 90% of clients book by appointment only, begins with a consultation. You’ll go into the shop and have a conversation about what you’re looking for, whether it’s a something for a wedding, a business meeting, or a graduation.

“The bespoke process really starts when I ask them how they want to be immortalized on their big day,” said Burnette. “We begin to understand their personality and what would be a great fit for them. We’ll spend 45 minutes talking about the garment is for before we even get to the measurements.”

You’ll also do a basic fitting with a jacket that is partially deconstructed so the clients can see what their fit preference is. “Some people’s vision of tailored may be much different from your vision of tailored,” said Burnette.

Once the pieces are commissioned, the client will come back two more times over an 8- to 10-week period for more measurements and fittings, and to select the details. Everything from lapels and pockets to buttons, lining, and stitching are hand-selected in the bespoke experience. This investment runs about $2,800 to $3,500, keeping in mind these are suits you can wear for the rest of your life.

“Our goal to make sure these suits outlast you,” Burnette said.

- Local Faces of Fashion

- The Hidden World of Raleigh Speakeasies

- Spooktacular Sights and Sounds

- On the House

- Down the Road: Sylvan Heights Bird Park

- Out & About in Wake County: September / October 2022

- Small Business Spotlight: ShopSpace

- Pay it Forward: Designed for Joy Lifts Women in Crisis

- Celebrated Spirits: Macaluso

- Celebrated Spirits: Fraise Juice from Compass Rose Brewing

- Garden Adventurer: Conversation Piece: The Ginkgo Tree